A leading automotive parts manufacturer faced critical challenges in packaging diverse repair kits containing rubber, rubber-reinforced, polyurethane foam, and silicone components. Key requirements included:

1. Flexible Packaging: Handling sets from 1pc to 12pc, part sizes from 20mm (min) to 380mm (max), and weights from 2g to 1069g in polyethylene bags (sizes: 100×100, 140×150, 200×200, 385×200).

2. Automated Processes: Needing automatic bag resizing, sealing (back seal + airplane hole/Euro Slot), trimming, and labeling.

3. Dual Labeling: Applying two labels per bag (50x80mm & 20x40mm).

4. Quality Control: Integrating a checkweigher for weight verification.

5. High Output: Achieving a target capacity of 8785 pcs/day.

6 .Feeding Flexibility: Requiring both vibratory bowl feeders and manual belt loading options.

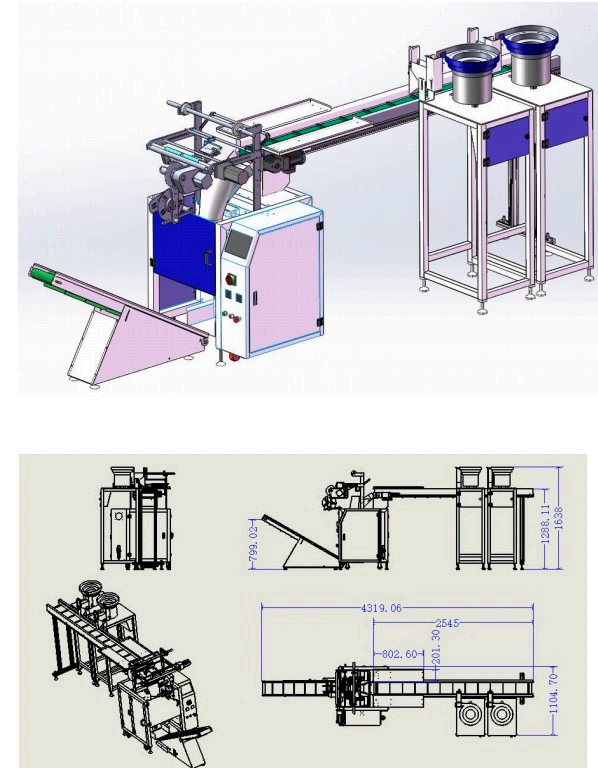

We engineered a high-performance, customized packaging system combining vertical and horizontal technologies:

•Automatic Vertical Packaging Machine: Featuring a 2.5-meter belt conveyor and two vibratory bowl feeders for precise counting and handling diverse part types and set quantities. This machine performs bag forming, filling, Euro Hole Opening sealing, cutting, and primary labeling.

•Horizontal Flow Pack Machine: Providing complementary packaging capabilities, especially suited for specific part geometries or high-speed requirements.

•Dual Labeling System: Two high-speed labeling machines integrated seamlessly to apply both the 50x80mm and 20x40mm labels accurately on each bag.

•Checkweigher: Integrated with the vertical line for real-time weight inspection, ensuring every kit meets the 2g-1069g specification.

1.Unmatched Flexibility & Adaptability:

•Handles extreme part size and weight variations within a single automated packaging line.

•Automatic bag size changeover between four standard dimensions.

•Hybrid feeding: Vibratory bowl feeders for efficient sorting and a belt conveyor for manual loading of complex parts.

•Accommodates rubber, foam, and silicone materials reliably.

2.High-Speed Production & Efficiency:

•Combined output of vertical and horizontal machines exceeds 8785 pieces per day.

•Fully automated packaging process (counting, bagging, sealing, cutting, dual labeling, checkweighing) minimizes labor and boosts throughput.

•Automatic bag length sensing optimizes film usage.

3.Enhanced Quality & Traceability:

•Dual labeling system ensures accurate and compliant product marking.

•Checkweigher integration guarantees consistent kit weight, eliminating errors.

•Electro-pneumatic control with automatic parameter monitoring and data archiving provides full process control and traceability.

4.Optimized Footprint & Reliability:

•Compact design combining vertical packaging machine and horizontal flow pack machine saves valuable floor space.

•Distributed workload extends equipment lifespan and enhances overall system reliability.

This turnkey packaging solution from Double Machinery successfully addressed all client challenges:

•Achieved fully automatic bag resizing and Euro Hole (airplane hole) sealing.

•Implemented hybrid vibratory feeder and manual belt feeding.

•Integrated high-speed dual labeling and precise checkweighing.

•Consistently met the 8785 pcs/day production target.

•Provided robust electro-pneumatic control with data monitoring.

The client fully approved the solution, praising its efficiency, flexibility, and ability to meet their complex automotive parts packaging requirements.

Contact: Ada

Phone: 86 15217651852

E-mail: [email protected]

Whatsapp:008615217651852

Add: Nanhai District, Foshan,Guangdong, China

We chat